Description

The T10 AirLift Exhaust Fan w/ Temperature and Humidity Controller is powered by AC Infinity.

Eliminate moisture and excess heat with our state-of-the-art computer-modeled design.

This powder-coated galvanized steel framing kit allows the T10 AirLift Exhaust Fan to be installed anywhere on shipping container sidewalls and end walls – from floor to ceiling.

- A high-airflow exhaust fan designed to ventilate out heat, moisture, odor, and dust from various spaces.

- Programmable controller with corded probe, can adjust fan speeds in response to temperatures and humidity.

- Innovative EC-motor with PWM-control maximizes airflow while reducing energy consumption and noise levels.

- Features steel shutters, aluminum blades, and IP-44 rated to be highly resistant to liquid and dust.

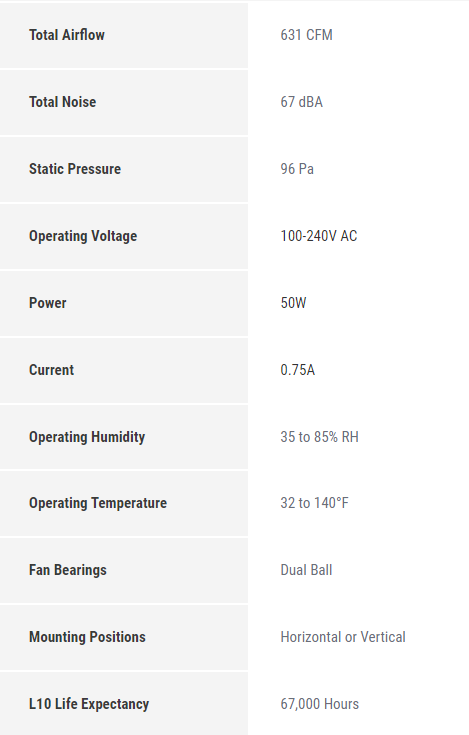

- Fan Size: 10” | Dimensions: 13.0 x 13.0 x 5.9 in. | Airflow: 631 CFM | Noise: 67 dBA | Bearings: Dual Ball

The 10" Aluminum Gravity Louvers are also designed to be installed anywhere on shipping container side walls, end walls, or doors – from floor to ceiling.

The T10 Air Lift Exhaust Fan w/ Temperature and Humidity Controller comes with a marking guide to make cutting a hole as easy as possible! Rivets and self-tapping screws are also included (we recommend using rivets).

The variables inside a shipping container are always changing. When the combination of those variables creates an environment prone to humidity, condensation will happen. The above-mentioned variables include, but are not limited to the following:

-

Humidity

-

Interior temperature

-

Exterior temperature

-

Wind direction

-

Wind speed

-

Foundation

-

Adequate airflow under the container

-

Direct sunlight to the roof

-

Direct sunlight to walls/doors

-

Type of contents stored

- The volume of contents stored inside

- Color of container

- Number of stock vents in the container

Unfortunately, stock container vents are not enough to prevent condensation. Typically, used containers have between 2 and 4 vents, and the actual total air passage hole is about the size of a dime. These vents are designed to keep sea water out and are meant more as a method to equalize pressure than to exchange air.

The T10 Air Lift Exhaust Fan w/ Temperature and Humidity Controller is truly a groundbreaking, powerful solution for ventilating shipping containers!

Warranty

Electrical parts are not covered by warranty after purchase unless there is a manufacturing defect.

Included Hardware

- Steel/Steel, 3/16", 1/2", Open Rivets

Installation Instructions

T10 Installation Instructions

Short Link

https://containermodificationworld.com/t10-electric-fan